As a clean renewable energy source, wind energy has been paid more and more attention by all countries in the world. It has a huge reserve of 10 times more water than the total amount of water that can be exploited on Earth. In recent years, with the continuous maturity of wind power-related technologies and equipment upgrading, China's wind power industry has developed rapidly. Whether it is the cumulative installed capacity or the new installed capacity, has become the world's largest wind power market.

With the large number of wind farm equipment has been put into use, the operation and maintenance of equipment also poses greater challenges. However, wind farms are mostly located in remote areas, fan distribution is scattered, manual inspection mode not only has poor safety, workload, low efficiency and other problems, but also by the observation angle, can not be fully and timely detection of problems. On the other hand, wind power systems operate 24 hours a day, especially at night, and often require more manpower rationing to achieve 24-hour continuous management maintenance and emergency response capacity.

With the development of UAV technology and the application of different industries landing, the new inspection operation mode based on UAV is gradually emerging in the wind power industry, relying on the ability of drones to fly high altitude, long distance, fast operation, wind power practitioners can greatly improve the efficiency of inspection.

The application of drones has brought great convenience to wind power inspection, but it is not simply equipped with a drone, inspection work can be carried out smoothly. Drone wind power inspection development to this day, is still in the "people patrol mainly, machine patrol as a supplement" stage. With the gradual improvement of wind power operation and maintenance requirements, simplifying the inspection process and improving the inspection efficiency has become an important subject for the development of UAV in the field of inspection, automation intelligence will undoubtedly be an important direction for the development of UAV. In view of the current situation and shortcomings of traditional wind farm inspection, the introduction of 5G Hui eye wind farm intelligent inspection solution and practical application verification, to improve wind power efficiency, reduce downtime, to ensure safe operation is of great significance.

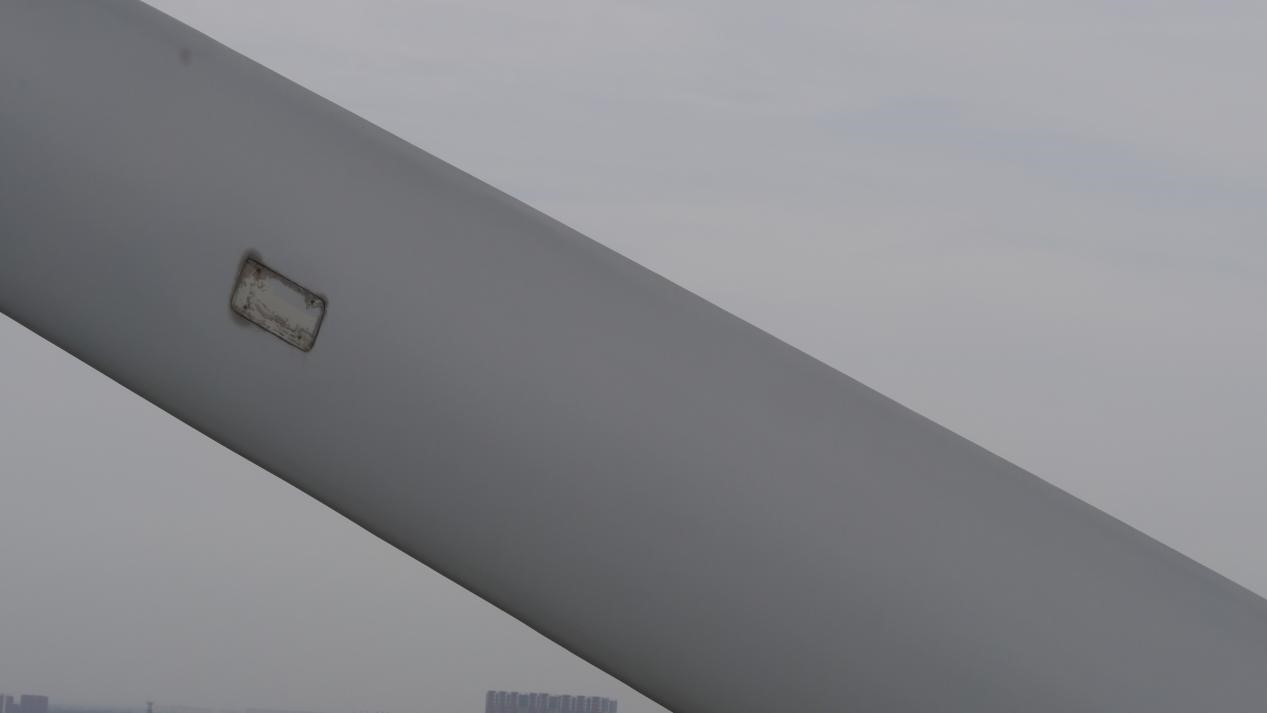

Wind power blades are generally installed in far areas, operating environment is harsh, such as large sand attack, -30 degrees to 50 degrees cycle temperature difference, as well as strong ultraviolet light aging, etc. , in the course of operation, the main types of faults of the field blades are lightning damage, blade icing, leading edge corrosion, overall structural failure, leaf tip drainage hole blockage, edge cracking, coating shedding, bolt break and fall.

For the fault form of wind turbine blades, the on-site blade fault inspection method is mainly visual inspection, the form is mainly divided into high-fold telescope inspection, high-altitude orbiting drop visual inspection ("Spider-Man"), blade maintenance platform inspection. Drones have the advantages of distributed inspection, stereoscopic observation and attention to imaging clarity.

Solution

In view of the characteristics of wind power blade detection, rotary-wing drones are suitable for wind turbine blade inspection due to their hover and low-speed flight capability. Multi-rotor drone with its easy control, easy maintenance, good economy, suitable for wind blade inspection of the main tool.

HC-332 oil-electric hybrid six-rotor UAV system is a high-performance multi-rotor drone product developed by Hive Aerospace Design, which has a four-hour long flight time, heavy load, high reliability, platform general, weather resistance and other industry-leading advantages. HC-332 is made of high-strength 3k carbon fiber material, equipped with a fully automatic flight control system, according to specific needs, to achieve air hover, autonomous route flight, one-click take-off, autonomous landing, can be equipped with differential GPS, cm-class precision control. The hybrid oil-electric system enables long flights. Widely used in agriculture and forestry monitoring, material delivery, electricity inspection, oil and gas inspection, security investigation and other fields.

The HC-321 intelligent drone inspection system guarantees storage, landing and charging of drones in the outdoor natural environment, ensuring that drones can operate around the clock and provide support for cluster control. The specific functions are as follows:

Storage of HC-321 drones;

Unmanned cabin through 4G equipment / ground network connection network, through the control center software can achieve cluster control;

Intelligent environmental awareness unit can monitor the wind speed, wind direction, temperature and humidity and rainfall outside the shutdown compartment in real time;

The high-precision reset device will accurately reset the drone that falls into the cabin to the specified position;

The lifting mechanism lowers the drone to the lower cabin to provide automatic charging (unbalanced charging) for the drone;

Up and down position combination control, convenient transport installation;

Wind and rain protection design, can store drones in the outdoor natural environment;

With self-test function can detect the door status, reset device status and control board status, to remind the error situation;

Intelligent switch cabin control, just click to complete the task or end the task to complete all the action control of the shutdown compartment;

Drones automatically plan route flights, saving a lot of manpower. Homeycomb proposed to rely on high-precision fixed-point fine inspection data (the point of each task is consistent, the operating accuracy is better than 0.5m; to obtain image consistency, control accuracy is better than 3 degrees), the resulting image data based on change and defects of automatic identification, can greatly improve the accuracy and operational efficiency of blade detection image data recognition.

At the same time, the UAV front-end data collection, back-end data management, application specifications and drone operations, such as unified management, the formation of a management platform, and comprehensively improve the level of information-based UAV power operations.

Honeycomb UAV Wind Power Intelligent Inspection, to drive innovation and development, with more accurate, safer, higher level of automation, information technology, intelligence, improve the safety of personnel and equipment, to help the construction and management of smart wind farm.

Real cases