Requirements analysis:

Railway is the main artery of our national economy, railway transportation has long played an important role in China's transportation. Therefore, railway safety, as a matter of concern to the country and people's lives and property, has been paid attention by the state and the Ministry of Railways. With the deepening of reform and opening-up and the development of the national economy, the hidden dangers of various public security accidents in railway transportation are gradually increasing, and all kinds of unexpected and accidents exist in the inspection of basic road conditions such as railway foundations, railway tracks, forks, signal lights, railway bridges, railway lines, etc.; Although the management center allows regular inspections by maintenance staff, the proportion of accidents is high due to the limited number of staff, limited energy and harsh environment in individual areas. Drones can take high-viewing and surround shots on the target railway, check the structure of railway equipment and safety hazards by taking video and photos at close range, break the time-consuming and costly mode of traditional manual inspection methods, and effectively improve work efficiency, especially in the terrain and terrain of dangerous and complex line inspection, site survey, hidden dangers and other aspects of the effect. Therefore, the use of drones for automatic railway inspection instead of manual regular inspection, is undoubtedly a powerful measure to eliminate all kinds of safety hazards.

Inspection UAV

Hybrid power multi rotor UAV

HC-332H adopts the oil-electric hybrid system, is a six-rotor UAV with universal mounting capability, can carry different mission loads to complete normal inspection, two-dimensional/ three-dimensional aerial survey, special equipment carrier and other tasks, the platform has full autonomous flight capability, for the railway fine inspection platform.

Multi rotor UAV specs:

Short-distance patrol, small range, micro-shooting;

Hover, take pictures at a fixed point, transmit video in real time;

With wireless video transferring, timely grasp of the scene dynamics;

Lightweight, easy to carry, flexible operation, suitable for finding fault points or checking the line conditions;

For swamps, water and other artificial inspection difficult special terrain, geomorphological pole tower, can complete the inspection task.

VTOL fixed wing UAV

HC-521 is a VTOL UAV with universal mount capability, which gets rid of the dependence of conventional fixed-wing UAVs on runways, can carry different mission loads to complete high-definition video capture and real-time backhaul, and the platform has full autonomous flight capability, which is a railway channel inspection platform.

VTOL fixed wing specs:

Suitable for large-scale inspection, macro-viewing transmission line corridor situation;

With long- endurance flight and GPS navigation function;

Fixed-point, fixed-range photography or real-time transmission and preservation of high-definition video, 4G network transfer to emergency response center;

Take-off mode: vertical take-off and landing;

Fully autonomous flight and strong wind resistance.

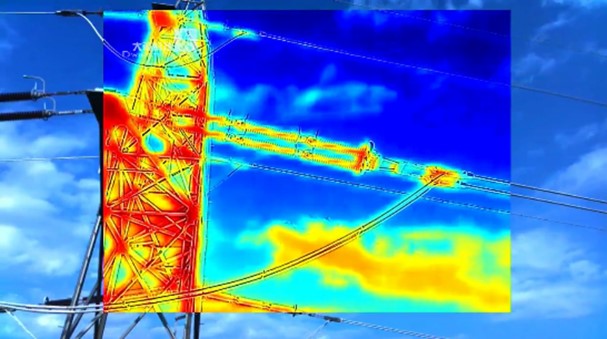

Visible light and infrared dual-light camera

Q30F 30x camera with high-precision professional three-axis stabilization zoom pod, using high-precision encoder FOC control scheme, with high stability, small size, light weight, low power consumption characteristics. The camera is available in 4 million effective pixels, supports 30x optical autofocus, and HD 1080P recording.

Tilt 5 lens camera

HCMC-003 tilt camera using mature and reliable industrial design and manufacturing process, the use of industrial-grade ABS material body, through modular body assembly design, equipped with multiple sensors, to achieve high-precision, wide area coverage, high efficiency aerial mission shooting. Can adapt to a variety of weather and natural environment under the aerial mission, for the railway channel geographic information acquisition equipment.

LiDAR

The airborne LiDAR provides fast access to high-precision 3D point cloud data for transmission line channels, and because of the vegetation-penetrating characteristics, it helps to accurately model trees, terrain, pole towers, wires, etc. in the channel, providing accurate flight navigation 3D maps for automated drone inspections.

Inspection solution

The use of drones has helped patrol crews improve inspection efficiency, but new ways of working have also created new challenges.

Drone inspection requires long flight control operations of drones, which require high levels of drone operation skills for grass-roots team members. Accidents such as "bombing" and "crashing tower" are also increasing with the expansion of aircraft patrol business. Under the premise of safe flight, the same line may also produce very different inspection conclusions after the master and novice fly by.

A team of drone patrol teams is typically staffed with about three people.

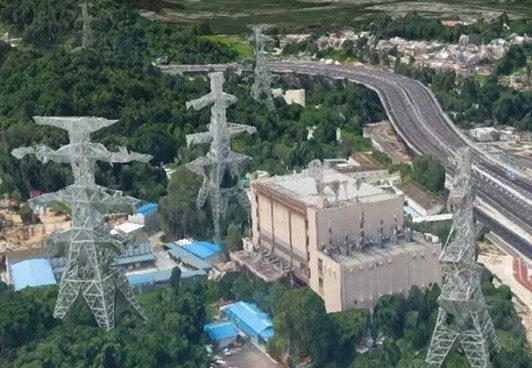

Channelized inspection

Using fixed-wing/multi-rotor drones and tilt camera/lidar, high-resolution accurate mapping of the target area can be used to provide accurate basis for railway line planning;

通道化巡检致力于发现以下问题:

是否有违章建筑,导线与建(构)筑物安全距离是否满足要求;

是否有超高树木,树木与导线安全距离是否满足要求;

线路下方或附近是否有危及线路安全的施工作业;

线路附近是否有烟火现象,是否有易燃、易爆物堆积等;

是否出现新建或改建电力通信线路、道路、铁路、索道、管道等;

线路防洪、排水、基础护基等是否坍塌、淤堵、破损等;

线路通道附近是否发现洪水、泥石流、山体滑坡等自然灾害;

巡线道、桥梁是否损坏。

成果展示

精细化巡检

采用多旋翼无人机+可见光/红外载荷,另可配备RTK高精度实时差分定位系统,实现对杆塔销钉、绝缘子等细小位置的定点精细化巡检。

精细化巡检致力于发现以下问题:

杆塔部分是否存在螺栓丢失、严重锈蚀;

绝缘子是否存在伞裙破损、放电痕迹、弹簧销子缺损、钢帽裂、污秽等;

线路是否存在散股、断股、损伤、断线、放电烧伤、悬挂漂浮物、严重锈蚀、导线缠绕(混线)、覆冰、雷击故障点;

防鸟装置是否缺失、损伤、变形等。

成果展示